Based In California – Serving The World

Download our equipment list and see why globally recognized companies choose USP to mass produce their customized parts and components.

Assembly, Kitting, & Finishing

U.S. Precision is truly a turn-key solution for metal fabrication offering in house services including but not limited to finishing, assembly, and kitting.

Our Capabilities

- Fastening and assembly

- Wet painting and powder coating services

- All plating processes

- Magnetic particle testing

- Heat treating

- Silk-screening w/artwork production and screens

- Identification per MIL-STD-130

- Engraving

- Hardware or additional media aggregation

Going From Production To Purpose

Our attention to detail extends from making your metal parts to plating, paint, silk screening, and assembly solutions. Most of the high-quality parts we fabricate need to be properly finished in order to meet standards, offer durability and protect against corrosion, be aesthetically pleasing, function properly, and contribute to the overall end user-experience.

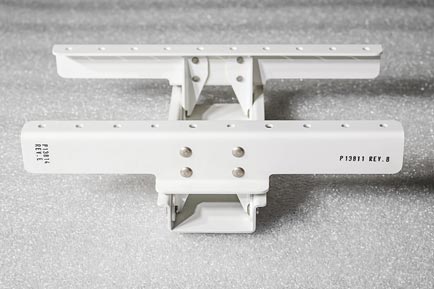

Putting It All Together

Once we have produced customized parts, our assembly team takes the reins. Painting is done as per specifications, hardware is acquired.

Fastening parts together with rivets, bolts, and screws is performed. All of this happens under the watchful eyes of our account managers and Quality Control team.

Kitting Services

Kitting may occur when a component or group of components requires additional parts prior to final assembly or installation which are outside of U.S. Precisions realm of services.

Decrease your company’s lead times and overall costs by allowing U.S. Precision to pass along a project to your additional resources by taking advantage of our kitting services. We can make sure that when your project is ready for the next stage by including wiring harnesses, additional fasteners, and other required media/small parts.

By identifying cost-effective kitting opportunities, U.S. Precision is once again providing a money-saving solution to our valued clients throughout the production process.