Based In California – Serving The World

Download our equipment list and see why globally recognized companies choose USP to mass produce their customized parts and components.

CNC Punching

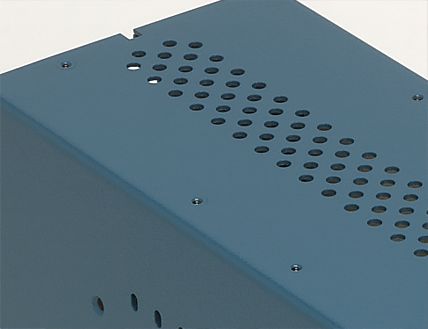

Our turret punch is capable of creating mass production parts and components with varying hole sizes, countersinks, depressions, extrusions, knockouts, and edges. Precision and repeatability are achieved through our inventory of over 5,000 punch and die sets. The results have clean edges and specific metal thicknesses and dimensions – all made according to our customer specifications.

Our CNC Punching Machinery

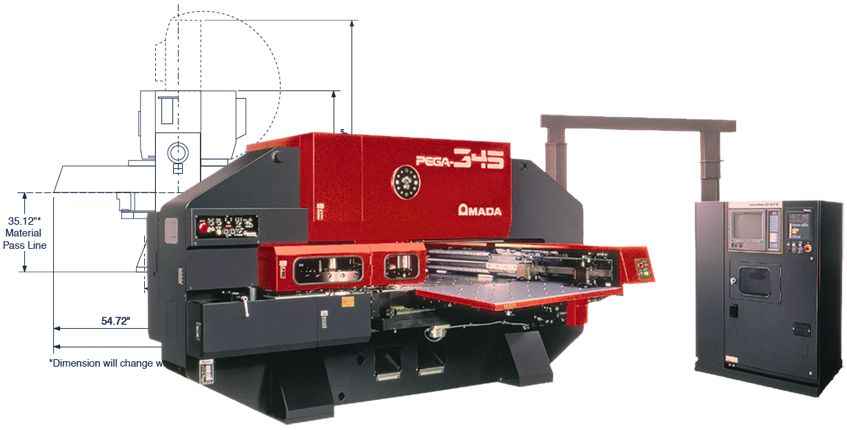

Amada Pega 345 King

Our Amada Pega 345 King CNC Turret Punch has a maximum sheet size of 40” x 50” and can punch through a sheet thickness of .25”. The machine is capable of 475 nibbling hits per minute and its max tool diameter is 4.5”. For addtional CNC Punching / Turret Punching details regarding your project, contact us today.

About Our Turret Punch

- Capacity: 33 Tons

- Max Sheet Size: 40 x 50" (40 x100" w/repo)

- Max Punching Capacity: 1/4"

- Max Hole Size (10 ga.): 3.5"

- Turret Speed: 30 RPM

- Turret Stations: 58 Stations w/ (2) A/I

Precisely Fabricated CNC Punched Parts

CNC punching can be done on different types of sheet metal, providing our clients with even more options for customization. Some examples include aluminum, stainless steel, mild steel, galvanized steel, and copper.

The CNC punching method is more cost effective than laser cutting but a turret press can only provide a hole or cut for which a tool or die exists. Minor forming can also be done on our CNC punch machine. Complex cutting paths must be done via our laser cutting equipment and the majority of forming or bending will take place on one of our many press brakes located on-site.

Shearing

Shearing is simply cutting down sheets of material down to smaller sizes. U.S. Precision uses an Amada M-2545 8′ shear with air-assist arms.

The machine is capable of trimming down sheet from an original length of 98.45in/2500mm. The programmable back gauge and squaring arm ensure straight, clean cuts at a rate of up to 60 strokes per minute.