Based In California – Serving The World

Laser Cutting

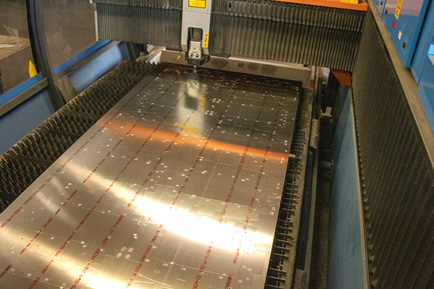

Our Laser Cutting Machinery

| Prima Platino Laser | Prima Synchrono Laser | |

|---|---|---|

| Sheet-W: | 60" | 60" |

| Sheet-L: | 120" | 120" |

| Wattage: | 5000w | 4000w |

| IPM: | 5551ipm | 3973ipm |

| X-Travel: | 120" | 120" |

| Y-Travel: | 60" | 60" |

| Z-Travel: | 9.5" | 5.9" |

| Dimensions: | 135" x 387" x 106" | 132" x 228" x 98.4" |

| Weight: | ~26,500 lbs | ~40,000 lbs |

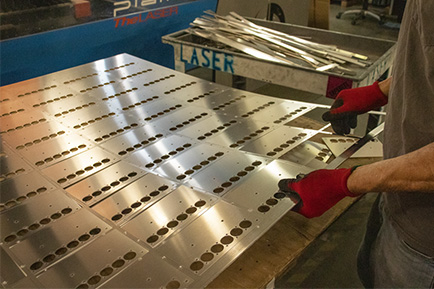

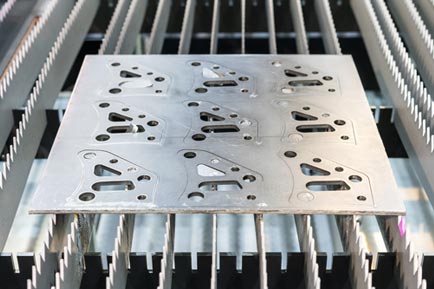

One of the best things about laser cutting machines is their ability to make parts in numerous sizes. From items, the size and thickness of a credit card to larger pieces that are several feet wide or long, the machine can be customized to handle it. This provides our clients with plenty of options when it comes to getting the parts that they need.

Our laser cutting process starts with the client’s vision. Our design and programming teams work with them to develop the initial design for the needed part. From there, some guidance and input are provided on possible metal and design choices on our behalf in order to optimize the creation of each part. After the client is satisfied with the finalized design, it goes into production on our state-of-the-art machinery.